News | 21.08.2024

Smart Factory – Get to Know the 3 Success Factors

by Henning Heine, Smart Factory Expert at MaibornWolff. Understanding the key success factors for smart factories is essential in today’s rapidly evolving industrial landscape.

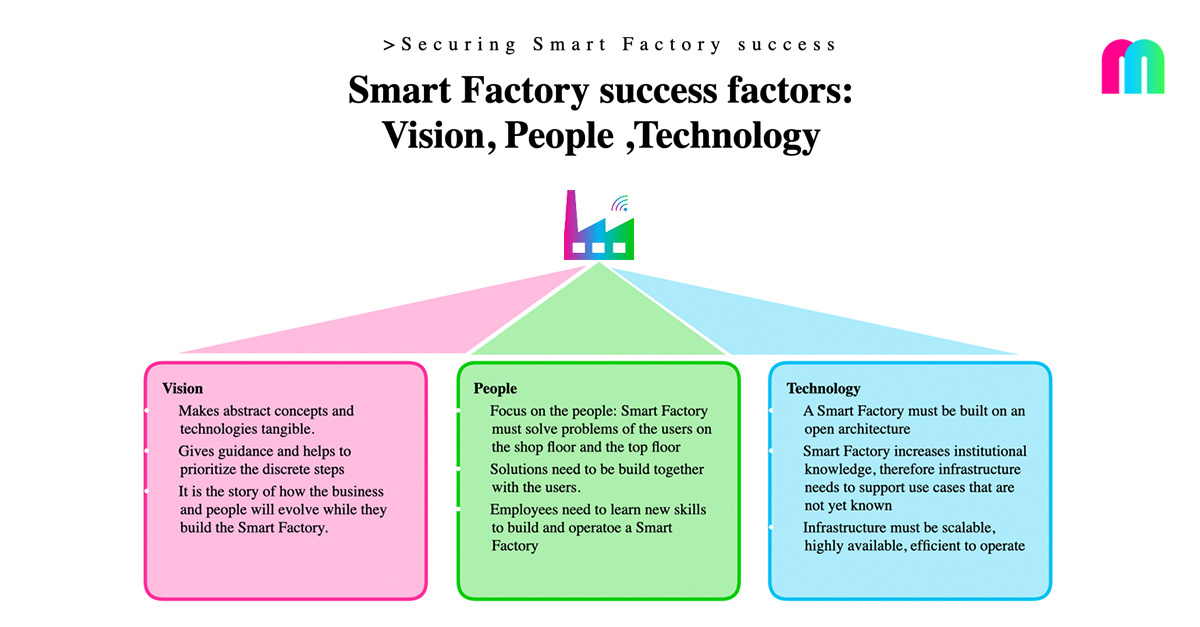

Henning discusses in this article the three key success factors for building a Smart Factory: Vision, People, and Technology. He highlights especially the necessity of a dedicated organizational setup, referred to as the Smart Factory Delivery Organization, which ensures continuous collaboration between IT and OT (Operational Technology). The article further explores best practices for aligning IT and OT to achieve Smart Factory success.

„There are three main success factors when building a Smart Factory: Vision, People and Technology.“

Creating the right organization to build your Smart Factory

Technology is easy

The technology part is pretty much solved by now. IIoT technology is reliable and has been tried and tested in all kinds of setups in the last couple of years. We have concepts and architectural patterns that we know will work for building a reliable, highly available and scalable infrastructure and for modern user-friendly applications.

Technology is easy, but people are the big element of uncertainty when building a smart factory. You can have the latest tech designed by bright architects and built by the best developers. If the people driving production are not properly involved in creating the smart factory, your initiative will fail.

A compelling vision brings people on board – key success factor vision

The big question is, how to get them involved and what should the organizational setup look like to ensure Smart Factory success. A compelling vision of the smart factory is one tool to get buy in from the colleagues. The vision should become a shared goal for all colleagues, from different parts of the business. To make this happen, it is not enough to put a vision statement on some PowerPoint slides and just proclaim it once. It needs constant explaining and campaigning, especially from the top management, to embed the vision in the people’s minds and hearts. Management needs to be the first and most passionate explainer of why building a Smart Factory is important for the company and for the people.

Organizational setup to keep the people involved

Coming to the organizational setup. This is probably one of the most difficult tasks, but also one of the most important ones, when starting a Smart Factory initiative. Building a Smart Factory boils down to converging IT and OT domains. Therefore, it is obvious that these two domains need to move closer together. If your company is still trying to drive the Smart Factory solemnly either from IT or the OT side, you might want to rethink your approach.

- IT cannot successfully introduce new technology without properly involving colleagues from operations. They are too far away from the shop floor to understand where the real pain points are, that could potentially be solved with digital solutions.

- OT colleagues, however, are very good at building solutions that help them keep production running. But as soon as it comes to digital solutions, OT depends on IT to provide at least the infrastructure to run them. Alternatively, they can build a shadow IT-system, but that really is in the interest of no one. Those systems are most likely not up to any security standard, and they consume time to be built and maintained, that would be better spent focusing on improving the production process.

IT and OT colleagues need to work together to build a Smart Factory. But it is not enough to just create a project team made up of people from different departments. Projects come and go and so does the focus of each individual project member. Loyalty to the respective department will always be stronger than loyalty to the project. This is especially relevant for longer running projects.

Smart Factory Delivery Organization

To prevent shifting focus, it needs a dedicated team that is tasked with bringing the Smart Factory vision to life. Let’s call it the Smart Factory Delivery Organization. This team must not just be a think tank, creating ideas or building POCs and throwing them over the fence to other departments to implement them. This team’s purpose is to design and implement the infrastructure and digital solutions that will allow the company to become more efficient and resilient. To be able to do so, the team needs a good mix of OT and IT expertise:

- Lead: Either from IT or OT with broad knowledge of both domains and a long-term view on how Smart Factory solutions can help the business.

- OT: To successfully design, build and implement digital solutions for the shop floor, it needs colleagues that know the pain points of the operators working on the machines and in the assembly lines. These OT experts represent the shop floor colleagues towards the development team. They are the first users to test a new solution, and they are also the ones that will help the users on the shop floor to adapt to it.

- IT: To efficiently develop and deploy applications that can potentially be deployed continuously, potentially across multiple sites, the team needs architects and developers that are experienced with DevOps methodologies. They should also bring good understanding of the systems that drive production as well as OT protocols, that they might need to interface with. Finally, the Smart Factory Delivery Organization needs colleagues that can build and operate a reliable and scalable infrastructure, that support all potential solutions that are being created on the way to build the Smart Factory.

Maibornwolff

Henning Heine

Smart Factory Expert

Henning Heine works as Lead Smart Factory Expert at MaibornWolff. He has been developing customised Smart Factory applications with and for employees on the shop floor for over 7 years. Henning networks machines and processes throughout the entire ISA95 stack, from the PLC to the ERP system and into the cloud. He focusses on the close exchange with users in production in order to transfer the experiences of employees into new applications and to increase the acceptance of new tools among users. Henning specialises in the use of low-code platforms in production and their embedding in the IIOT infrastructure. As a mechanical engineer with many years of experience in manufacturing companies, he supports customers on their way to the smart factory.

The article was first released in June 2024 on LinkedIn and is only available in English.