in INTERVIEW

Felix Pfeiffer

Technical IT at the Handtmann Group

Felix Pfeiffer, Technical IT at the Handtmann Group, is primarily responsible for the digitization of production and digital transformation. The global manufacturing enterprise Handtmann is active in a wide range of business areas, from light metal casting to mechanical engineering and is a leader in digitalization and innovation.

SUCCESS STORY metal processing AND MECHANICAL ENGINEERING

Implementing traceability independently

Interview with Felix Pfeiffer from the Handtmann Group

Mr. Pfeiffer, why is traceability so important for your industry?

Traceability is an important milestone for single-part oriented data processing. With tracing individual parts, we create an extensive database that documents the manufacturing process of each component and makes it transparent. In addition, we create a trend-oriented database that allows us to gather correlations and trend-setting insights. In this way, we realize process optimizations and continuous improvements to our products. Reduced scrap, improved complaint handling, increased output and the associated reduction in costs are further aspects that highlight the importance and necessity of traceability.

What challenges impede the introduction of a traceability solution? And how have you solved them?

The basis of data generation is based on very complex connected plants and systems. This often makes it difficult to implement uniform and standardized solutions in the area of traceability due to their age, runtime and technical limitations. Also, technological progress and the continuous development of information technology continuously change “common practices” in the implementation of suitable solutions in IT and OT. In this context, it is all the more important to create robust and, in some cases, cross-protocol interfaces. With Cybus Connectware, we have the right product for this. Due to the range of supported protocols, the continuous development and the support by Cybus, we have already been able to master some of the challenges. The software gives us the freedom, which is so important for us, to create and administer corresponding services completely independently, flexibly and in a technically comprehensible way. Thus, we see ourselves equipped for further, existing and future challenges.

Traceability is an integral part of your production processes. What successes and results have you achieved?

At the moment, we are still working intensively on the development and expansion of traceability in our production processes. Nevertheless, we have already seen initial successes: For example, we have gained knowledge about process parameters that influence quality, from which we have been able to derive and take measures. We are also in a position to carry out more in-depth data analyses and to achieve the associated targets for reducing scrap. Additionally, we are able to implement condition-oriented individual parts processing based on the “intelligent plant” model.

“Having the right software makes a big difference in overcoming the relevant challenges.”

Felix Pfeiffer, Technical IT at Handtmann Group, implements an own traceability solution based on Cybus Connectware.

What technical factors were decisive for you in deciding on a strategic rollout of Connectware across several plants?

In addition to the already mentioned extensive support of numerous protocols, we chose Cybus solution because of its scalability, security, independent administration, technical depth and technical comprehensibility. Connectware complements our technical know-how excellently and offers us a tool that has so far met our expectations in all respects. Qualified and ambitious administrators are able to look behind the scenes of the product. This also allows to understand the product holistically and to take independent measures in case of potential complications. This freedom to help oneself and the generous independence that comes with it is a high priority for us. Also, we appreciate the personal contact with Cybus, as we can always solve problems quickly and successfully with qualified personnel and support.

Our ideas, requirements and comments about Connectware always find an open ear at Cybus. This allows us to help shape Connectware but also assures that we can always meet our internal requirements with Cybus.

What (technical) tips regarding digitization would you give to others in the automotive supply industry who are facing similar challenges in production?

The right software makes a big difference in overcoming the relevant challenges. Especially when it comes to connecting OT systems to IT systems and vice versa. Unifying the necessary core functionalities in terms of data acquisition, data processing and the comprehensive protocol support results in a powerful tool that can be conceptual and helpful in achieving individual goals. Of course, this also implies administration and support by qualified personnel. However, with extensive online documentation, expert support and continuous contact, Cybus offers everything that is needed here.

Mr. Pfeiffer, thank you very much for the interview!

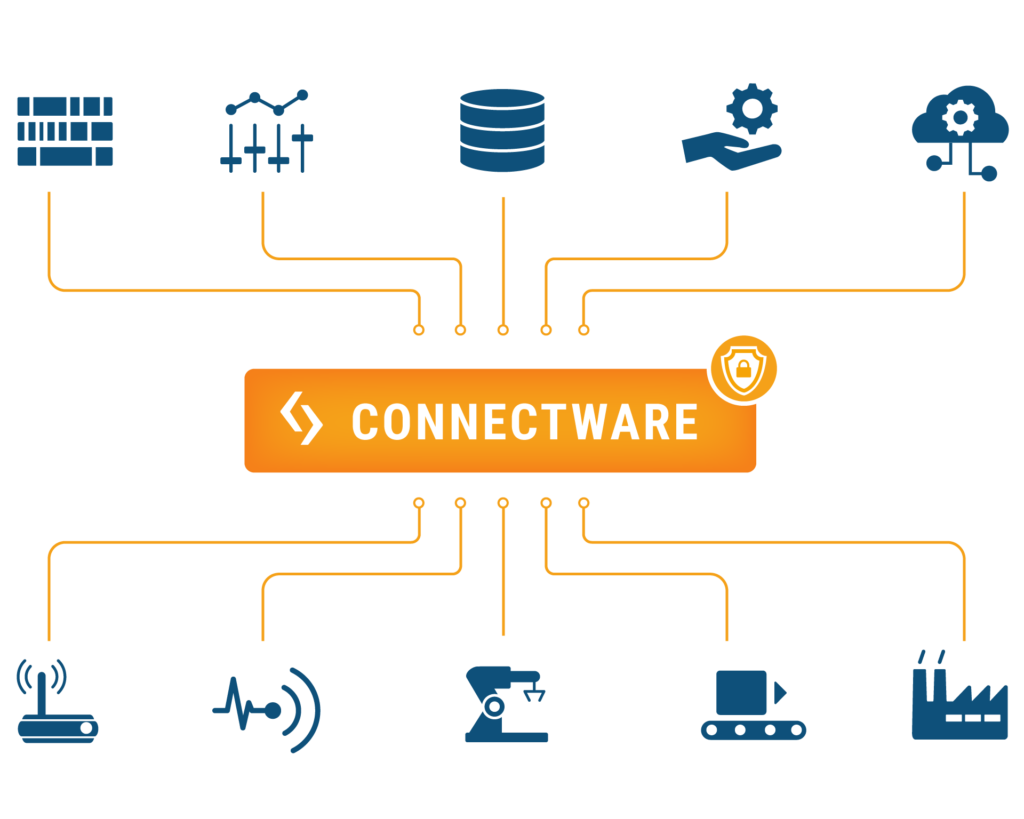

CYBUS CONNECTWARE

Trace the entire production with a scalable data infrastructure

One software for holistic connectivity

With the leading Factory Data Hub Connectware you realize your first steps of digitalization up to the Smart Factory transformation. In addition to full shop floor connectivity, Connectware also creates a scalable data infrastructure for your digital projects – without limits.

Start now with Cybus

Would you like to find out what you can achieve with Cybus Connectware in your factory? We would be happy to discuss your requirements and plans with you and guide you through the Factory Data Hub Connectware in a live demo.

you could be also interested in

Traceability with Cybus

Trace processes and ensure highest quality

With seamless traceability, you ensure all required standards and guidelines along the entire production chain. End-to-end quality assurance and labeling enormously simplifies future material recalls and makes effective process optimization possible.

Leading manufacturers rely on Cybus

Whether metal processing, automotive or toolmaking – leading manufacturers rely on the Factory Data Hub