-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCase Study Schunk GmbH

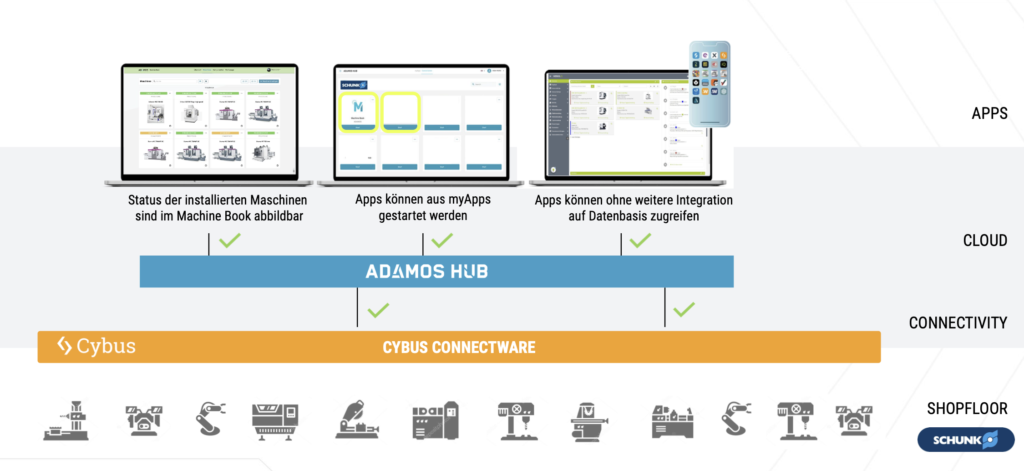

How Industry 4.0 works in practice is demonstrated by SCHUNK GmbH & Co. KG from Lauffen am Neckar, Germany. The global competence leader for gripping systems and clamping technology has used the networking technology from ADAMOS to integrally combine its production, which is connected via Cybus, with the maintenance and servicing software from WERKBLiQ, thus achieving an enormous gain in performance.

CYBUS CONNECTWARE

Cybus Connectware not only collects data, but also standardizes it to a common language, preprocesses it according to your requirements and distributes it to any system, application or cloud. As a result, you can instantly display your data on the dashboards, perform advanced analytics or machine learning.

Instead of finding an individual solution for each customer on the store floor, networking is done via the ADAMOS HUB. Using this advanced networking technology, Cybus Connectware was able to make the real-time data available to the ADAMOS HUB after only a few days of integration. The data is made available to the so-called “SCHUNK client” in the ADAMOS HUB and SCHUNK itself decides whether and how the data should be made available to the WERKBLiQ application. WERKBLiQ, in turn, can then process this data and provide the desired use case for the client. And vice versa. This principle also works for any other application from the ADAMOS STORE.

Networking of machines, data and apps – how can different solution providers offer their customers simple consistency and connectivity in production? Learn how real-time production data was seamlessly integrated into a maintenance software in the full case study.

Whether metal processing, automotive or toolmaking – leading manufacturers rely on the Factory Data Hub

With Cybus’ universal data infrastructure, our customers independently implement a wide variety of use cases. The Factory Data Hub enables the most complex digital projects and ensures a successful roll-out.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information