-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

WHITEPAPER | CLEVER ZUR SMART FACTORY

Transforming a factory into a Smart Factory means more than just implementing Industrial IoT use cases: Full-scale digitalization democratizes the individual layers of the automation pyramid and transforms them into a process-oriented structure. Discover exactly what this means and how you can pave the path to the smart factory for your company in this white paper.

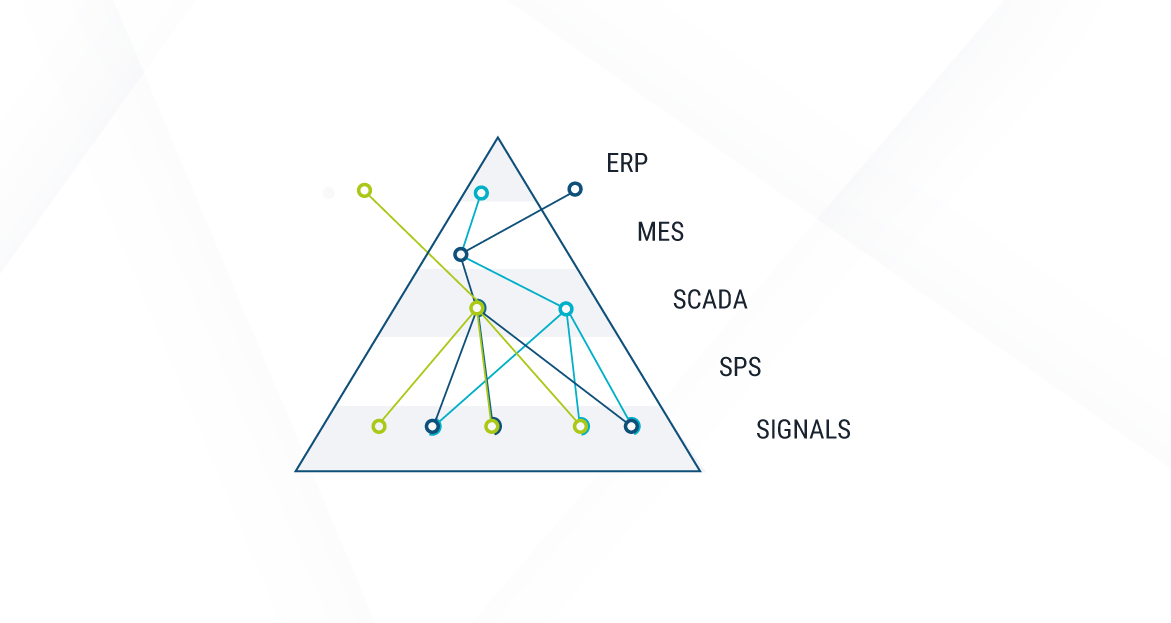

Automation often follows the automation pyramid approach. However, as technology advances, vulnerabilities in information transfer become apparent: There is a lack of consistent structures and connections between systems (such as an MES that should seamlessly links ERP and production systems).

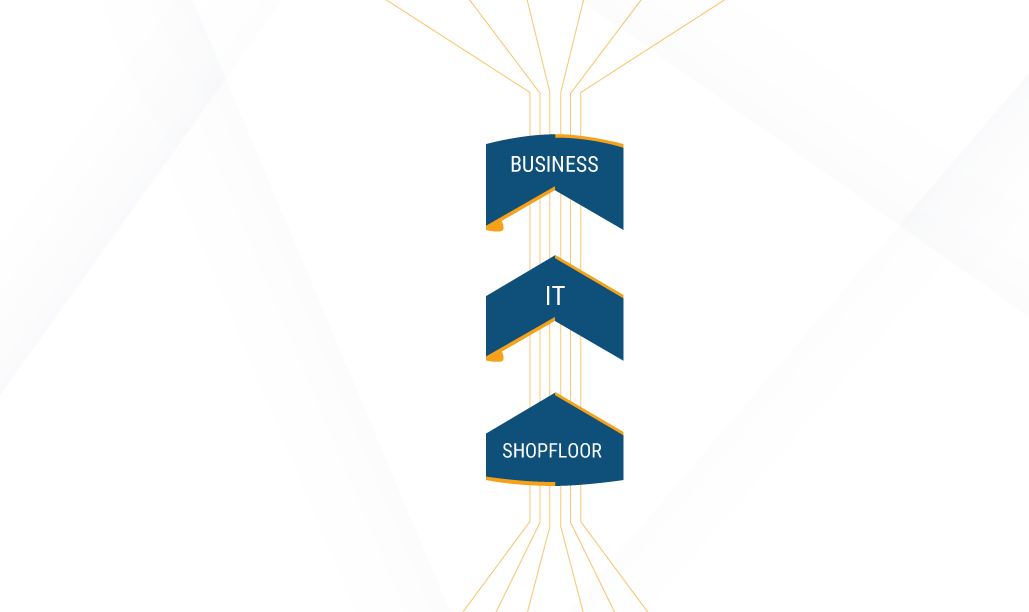

If a company integrates the three layers of business, IT and shop floor across processes and divisions, it can cope with the rapid dynamics of digitization. This agile structure enables fast and simple adaptation from PoC to roll-out and beyond.

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationFactory Data Hub

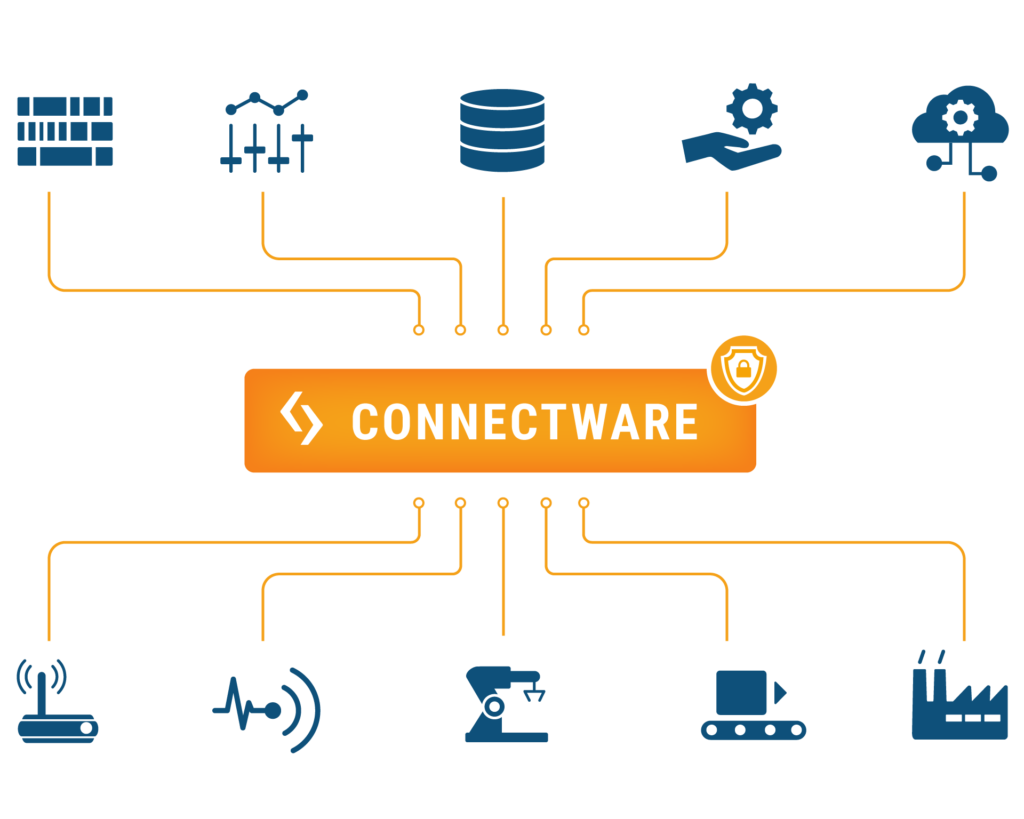

With the leading Factory Data Hub Connectware you can realize your first digitization projects as well as a holistic transformation to the Smart Factory. In addition to universal connectivity, Connectware creates a

scalable data infrastructure for digital IIoT projects – independently implementable.

Your initial situation and requirements are complex and unique. That’s why we want to understand you better in the first step.

Sales manager

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe success stories of our customers show how the strategic decision for a Factory Data Hub scales future-proof.

A scalable data architecture is above all a strategic decision: Talk to us about your projects and experience,

how the Factory Data Hub lays the foundation for your Smart Factory and provides all necessary resources.

Whether metal processing, automotive or toolmaking – leading manufacturers rely on the Factory Data Hub

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information