FlowSync ensures a closed communication loop where every request receives a reliable, traceable response. By seamlessly integrating event-driven and request-response workflows, it translates between industrial communication protocols like OPC UA methods and HTTP REST, ensuring full compatibility and precise process control. Cybus Connectware introduces FlowSync as part of our mission to provide a secure, flexible and efficient Factory Data Hub.

Let’s explore the advantages of using this unique feature with Cybus Connectware.

The challenge: increasing communication complexity and managing process dependencies

Manufacturing systems rely on flawless communication between shop floor technologies like PLCs and IT systems such as MES and OEE tools. Cybus Connectware has long been the benchmark for enabling this seamless interaction and continues to set the standard for robust and reliable system communication in industrial environments. However, as workflows become more complex and diverse, the need for advanced synchronization and decoupling has grown – and that’s exactly what Cybus has delivered.

Many manufacturing processes depend on causal execution steps, where Step A must be completed before Step B can begin, followed by Step C. Traditionally, ensuring this structured execution required custom logic, extensive manual intervention and individually defined request-response workflows. Each system had to be manually configured to provide feedback, making it difficult to maintain consistency and traceability across all process steps. As workflows become more advanced, manufacturers need a scalable, automated and fault-tolerant synchronization layer that eliminates manual effort to control process execution – while maintaining flexibility for upgrades and protocol changes.

The solution: Cybus Connectware’s newest feature, FlowSync and its closed communication loops

FlowSync extends Cybus Connectware’s industry-leading capabilities by introducing advanced synchronization for even the most demanding manufacturing environments. By enhancing Cybus Connectware’s HTTP and OPC UA server functionalities, FlowSync provides a powerful layer of decoupling and protocol translation, allowing systems to communicate seamlessly and evolve independently.

At its core, FlowSync ensures a closed communication loop where every request receives a reliable, traceable response. This innovation bridges event-driven and request-response workflows, translating between protocols like OPC UA methods and HTTP REST to ensure complete compatibility and process control. Even in complex scenarios, FlowSync maintains accuracy, transparency and reliability – eliminating the need for direct system modifications.

A practical example: synchronizing PLCs and MES

Consider a PLC that generates production data requiring processing by an MES system with an HTTP REST interface. In the past, tightly coupled communication would have demanded custom modifications to each system.

FlowSync transforms this process. The PLC sends data via OPC UA, which FlowSync translates into an HTTP REST request for the MES. Once the MES processes the request, FlowSync relays the response back to the PLC, converting it to OPC UA. This bi-directional flow ensures that each system remains decoupled while maintaining reliable and traceable communication. System upgrades or changes on either side no longer risk breaking workflows, as FlowSync bridges the gap.

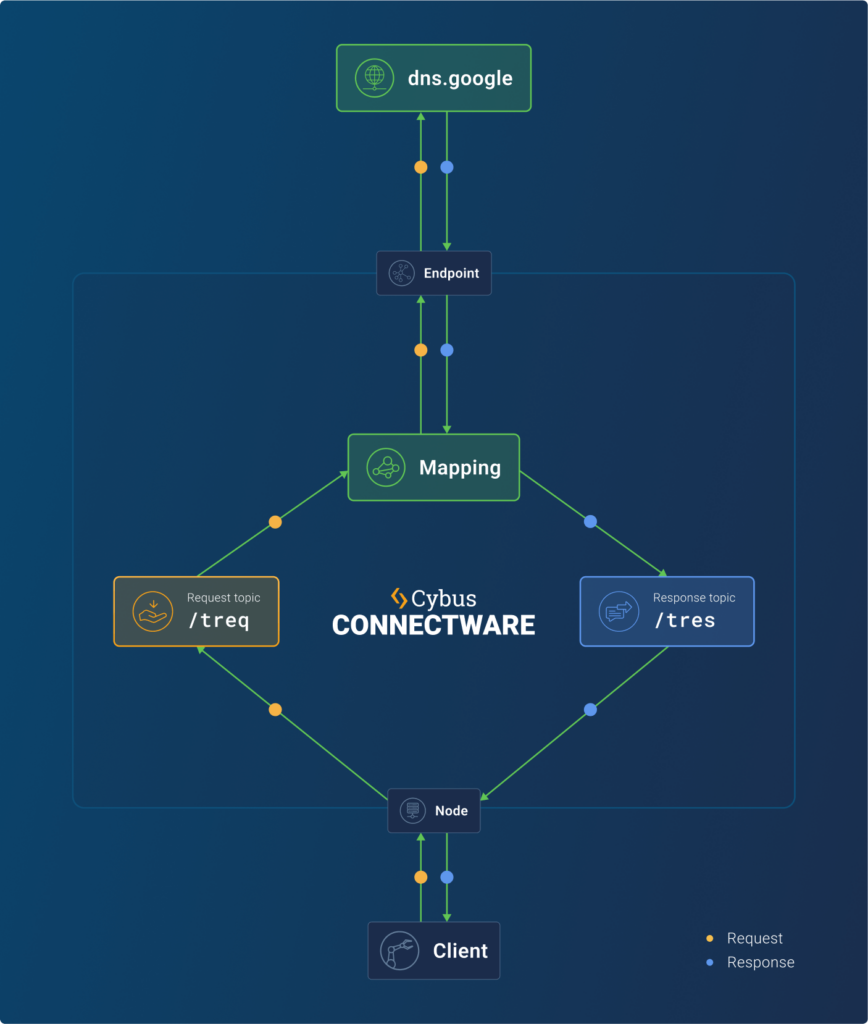

About the example: This example demonstrates a complete FlowSync implementation that creates a bridge between an external DNS service and a local endpoint as shown here.

The benefits of FlowSync – a summary

FlowSync takes Cybus Connectware’s performance to new heights, enhancing reliability, flexibility and efficiency in manufacturing communication:

- Protocol Refinement: With enhanced support for OPC UA methods and HTTP REST, FlowSync ensures compatibility with modern manufacturing systems and tools.

- System Decoupling: By acting as an intermediary, FlowSync allows systems like PLCs and MES to evolve independently without compromising communication.

- Reliable Communication: FlowSync’s closed communication loop synchronizes workflows, ensuring traceability and error handling at every step.

- Simplified Integration: Manual adjustments are no longer required, reducing complexity and streamlining system setup.

FlowSync is available with Connectware 1.9.0. Click the link below to visit our documentation and learn how to activate FlowSync, explore advanced technical configurations and see examples – all designed to take your system communication to the next level.