Set up the bedrock foundation for Smart Factories

The traditional automation pyramid, which structures manufacturing operations into hierarchical layers, is increasingly being replaced by integrated, data-centric architectures.

In the conventional model, data runs upward from sensors and actuators at the physical layer through control systems, such as PLCs and SCADA, to the enterprise layer, which includes Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP). This structure creates data silos and delays decision making.

Conversely, a Factory Data Hub sets up a new, centralized data architecture, which promotes seamless horizontal and vertical integration. Data flows freely across all levels and systems, from the shop floor assets to highest level enterprise applications and back. This real-time, bi-directional data flow increases operational flexibility, accelerates decision making, and enables rapid adaptation to market changes.

Adopting an Industrial DevOps Approach

Following the principles of DevOps, the new data-driven architecture emphasizes continuous integration and continuous delivery (CI/CD), and agile methodologies. The Factory Data Hub acts as a central component, enabling a seamless flow of information across different systems and stakeholders. Industrial DevOps extends the DevOps principles to industrial environments, particularly manufacturing and other industrial processes. It involves applying concepts from software development to industrial production to enhance automation, efficiency, flexibility, and quality in IT operations. Being based on Infrastructure-as-Code (IaC), the Factory Data Hub brings applies these software concepts and cloud technologies to the manufacturing environment.

Bringing Industrial DevOps to the factory

- Continuous Integration and Delivery (CI/CD):

With a Factory Data Hub based on IaC, software updates, configurations, and use case rollouts can easily be continuously integrated, tested, and deployed. This ensures a smooth and efficient production without downtime. By storing the configurations in a Repository like GitLab or GitHub, the accessibility of DevOps tools and the capability to automate rollouts, a Factory Data Hub innovates how manufacturers run and improve their production processes.

- Agility and Automation:

A modern data-driven approach in the manufacturing environment requires agile practices and automation. Continuous change is only possible if IT systems are able to quickly adapt while keeping production running. Companies with this capability are more efficient and competitive. For this, Industrial DevOps is the most powerful approach. It automates processes in IT operations, minimizes errors, increases efficiency, and reduces manual intervention.

- Collaboration and Communication:

For DevOps, various teams, including OT engineers, IT specialists, and operations managers, work closely together. This ensures that data insights are actionable and that operational adjustments can be implemented quickly. Fostering IT/OT Collaboration by defining processes within the cross functional teams of IT, OT and business improves production processes and instantly increases efficiencies.

The Factory Data Hub: The Heart of Smart Manufacturing

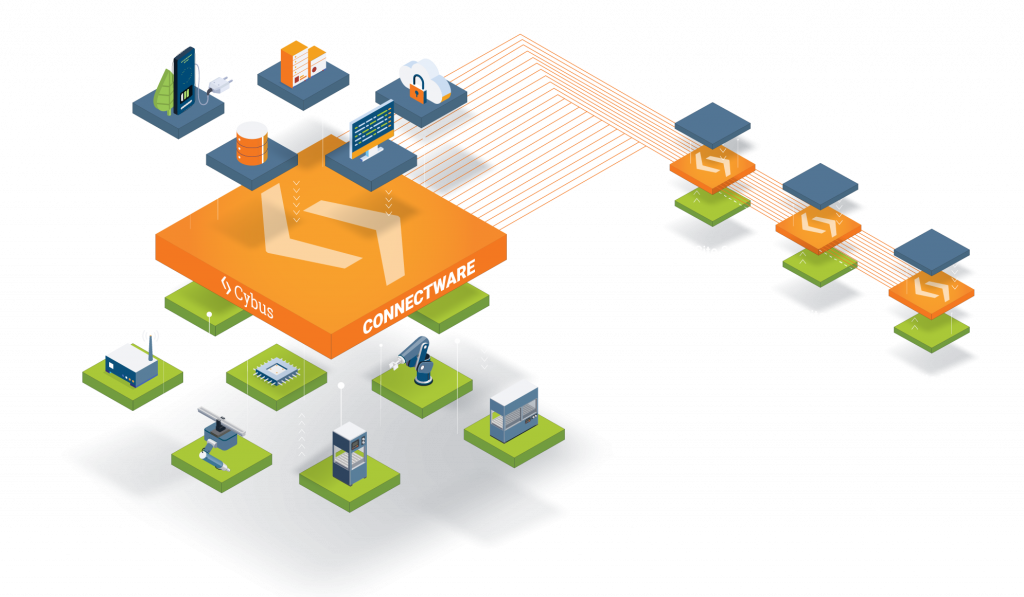

In the ever-evolving landscape of manufacturing, efficiency, scalability, and innovation are more critical than ever. Central to achieving these goals is the Factory Data Hub, a pivotal component that serves as the heart of contemporary production environments. A Factory Data Hub sets up connectivity, data integration, process optimization and automation. Hence, it is the core software to transform towards Industry 4.0.

- Seamless Connectivity

A Factory Data Hub excels in providing seamless connectivity across diverse devices and systems within a manufacturing ecosystem. In a typical factory, various machinery, sensors, and software platforms often operate in isolation. The data hub forms a central point of integration, ensuring that these disparate systems can communicate effectively. This interconnectedness allows for a cohesive and responsive production environment, where data flows freely and accurately throughout the entire manufacturing process. - Real-Time Data Integration

One of the most significant advantages of a Factory Data Hub is its ability to integrate real-time data from multiple sources. Timely decision-making is crucial in modern manufacturing. The data hub aggregates information from production lines, quality control systems, supply chain logistics, and even customer feedback channels. This comprehensive and up-to-the-second view of operations empowers manufacturers to make informed decisions quickly, adapt to changing conditions, and preemptively address potential issues. This minimizes downtime and enhances overall productivity. - Enhanced Process Optimization

Beyond connectivity and integration, a Factory Data Hub plays a vital role in process optimization. By feeding advanced analytics and machine learning algorithms with high quality data, users are enabled to identify patterns, predict outcomes, and suggest improvements. This continuous optimization leads to increased efficiency, reduced waste, and higher product quality. Manufacturers can fine-tune their operations, streamline workflows, and achieve levels of precision and productivity previously unattainable. - Scalability and Flexibility

The manufacturing industry is dynamic, with constantly evolving demands and technological advancements. A Factory Data Hub offers the scalability and flexibility needed to adapt to these changes. Whether expanding operations, incorporating new technologies, or shifting to different production models, a data hub scales and adjusts accordingly. Its modular architecture allows manufacturers to configure the system to their specific needs, ensuring they remain agile and responsive in a competitive market. - Facilitating innovation

As the manufacturing industry always progresses towards new trends and technologies, a Factory Data Hub is a crucial enabler. The software equips manufacturers with the infrastructure they need to optimize production, e.g. with the integration of all industrial systems, including state-of-the-art analytics applications or by configurations that can be automated. It transforms traditional factories into intelligent, interconnected systems, which are capable of continuously monitoring, analyzing and optimizing. This paves the way for a new era of manufacturing excellence.

Benefits of Implementing a Factory Data Hub

- Operational Excellence:

By providing real-time access to industrial data, the Factory Data Hub provides all prerequisites to improve overall equipment effectiveness (OEE), reduce downtime, improve product quality, and reduce maintenance costs. - Sustainability and CSRD:

Detailed monitoring of resource usage helps identify opportunities to reduce energy consumption, minimize waste, and support environmental goals. Furthermore the ability of complying with upcoming sustainability regulations like CSRD, ESRS or the energy efficiency law. - Agility and Innovation:

The flexible and scalable nature of the Factory Data Hub integrates the current software and system landscape of the enterprise architecture. It promotes early adoption of emerging technologies such as AI, machine learning, and advanced robotics and hence, ensures and creates competitive advantage. - Supply Chain Optimization:

Enhanced data transparency and traceability improves coordination with suppliers and distributors, resulting in cost savings and more reliable delivery schedules.

Connectware is the flagship software of a Factory Data Hub

The Hamburg-based software company Cybus launched the first Factory Data Hub on the market and is still a leader in the integration of large and complex industrial landscapes. The flagship software Connectware is the only data hub that can fulfill the automation, scaling and security requirements of a global manufacturing enterprise, thanks to its unique Infrastructure-as-Code architecture.

Already subscribed to our newsletter?

Receive monthly insights on:

- Keynotes from our experts with tips and best practices

- Podcasts and masterclasses on Industry 4.0

- Information on upcoming industry events