News | 25.04.2023

Recap of Hannover Messe 2023

Edge-to-Cloud Architectures, ESG and Partner Networks are the future of the Smart Factory

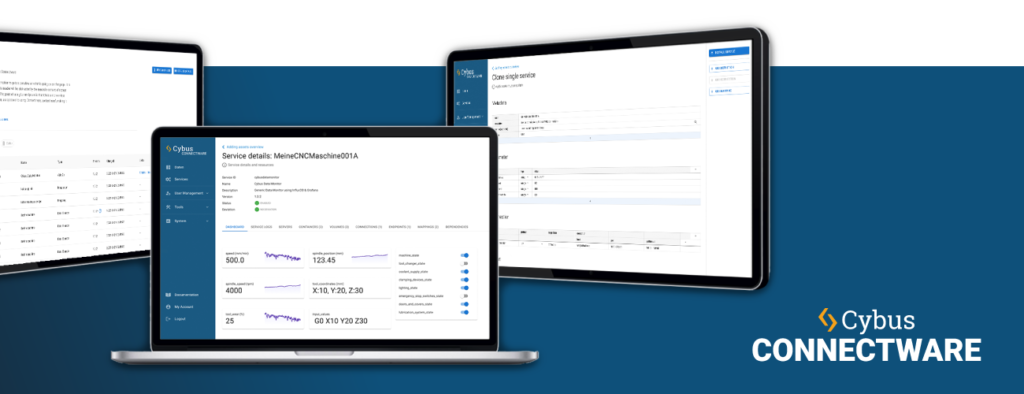

At this year’s Hannover Messe, Cybus focused on edge-to-cloud architectures, Environmental Social Governance (ESG)-compliant operations as well as energy management and partner networks. Cybus Connectware, the Factory Data Hub for end-to-end data flow between manufacturing and IT, attracted great interest this year due to its new user interface. Real-time data from production can now also be accessed independently by all stakeholders throughout the company.

This year, over 4,000 exhibitors from the mechanical engineering, electrical and digital industries as well as the energy sector presented technologies and solutions for a networked and climate-neutral industry. From the digitalization and automation of complex production processes to the use of hydrogen to supply energy to factories and the application of software to record and reduce the carbon footprint: it quickly becomes clear what is helping to shape the future of the smart factory.

The software company Cybus organized the five days of the trade fair with a rich program: Visitors could be guided live through the new user interface of the Factory Data Hub, which now also enables collaboration and real-time data use for stakeholders from the entire company. A demonstrator showed Cybus Connectware in use for direct machine connectivity and data analysis on-site at the show. And visitors had the opportunity to take away success stories from customers in the automotive and metalworking industries as inspiration for their digitization projects.

Experience live: Stakeholder collaboration with real-time data

The new user interface from the leading Factory Data Hub

At this year’s Hannover Messe, visitors experienced the new Cybus Connectware user interface live and up close in a demo. Use case owners, be it energy managers, controlling or quality assurance, will in future be able to access real-time data from production independently and use it for their own use cases. The premiere of the new interface aroused great interest and once again shows the importance of making collaboration possible throughout the company.

You couldn’t make it to the live demo or the Hannover Messe? Request your personal live demo afterwards and let our IIoT experts show you how to resiliently digitalize your production with the Factory Data Hub.

Industrial IoT use cases at your fingertips

Cloud-Integration, Connectivity, Cybersecurity and Quality Assurance

At several booths, Cybus Connectware again demonstrated its performance and compatibility with existing IT architectures. For example, visitors were able to visit the live installation at a partner booth, in which Connectware connects several industrial end devices and integrates the data into both an MES and Azure. Of particular interest to visitors was the network segmentation enabled, which simultaneously establishes strong IT security.

Visitors also experienced the software and the new user interface at the Cybus booth. Two use cases for automated machine connection and data integration between store floor, ERP and MES give an idea of the possibilities users have with the Factory Data Hub.

Receive monthly insights on:

- Keynotes from our experts with tips and best practices

- Podcasts and masterclasses on Industry 4.0

- Information on upcoming industry events

Gin & Tonic Networking-Event 🍸

Cold drinks and networking at the end of the fair day

It’s hard to imagine HMI without our Gin&Tonic networking event. The strong ecosystem around Cybus came together on the evening of May 18 to finish their impressions of the Hannover Messe. This evening also showed how much the topics of energy management, edge-to-cloud architectures and ecosystems are driving vendors and factory operators across a wide range of industries. The networking event was attended by Red Hat, DXC, PWC Germany, ISAX, Cedalo and many other companies.

We would like to thank all visitors for the valuable discussions and the great interest in Cybus Connectware.

Selected Cybus Connectware use cases at a glance

Discover the possibilities that a Factory Data Hub offers you

Leading manufacturers rely on Cybus

Whether metal processing, automotive or toolmaking – leading manufacturers rely on the Factory Data Hub